From pv magazine Germany.

The research project Printed Perovskite Modules for Building Integrated Photovoltaics – “Printpero” – is aimed at developing highly efficient and cost-effective solar modules.

The panels proposed would incorporate perovskite-based thin-film solar cells which achieve efficiencies of more than 23% in the laboratory, said the coordinator of the German-Greek research project, Germany’s Karlsruhe Institute of Technology (KIT). Similar processes developed in laboratory conditions have thus far proven unable to translate into commercial production.

“One goal of our project is, therefore, to replace the laboratory processes with digital printing processes that run at low temperatures and are suitable for industrial production,” said Printpero coordinator, Ulrich Paetzold, from KIT.

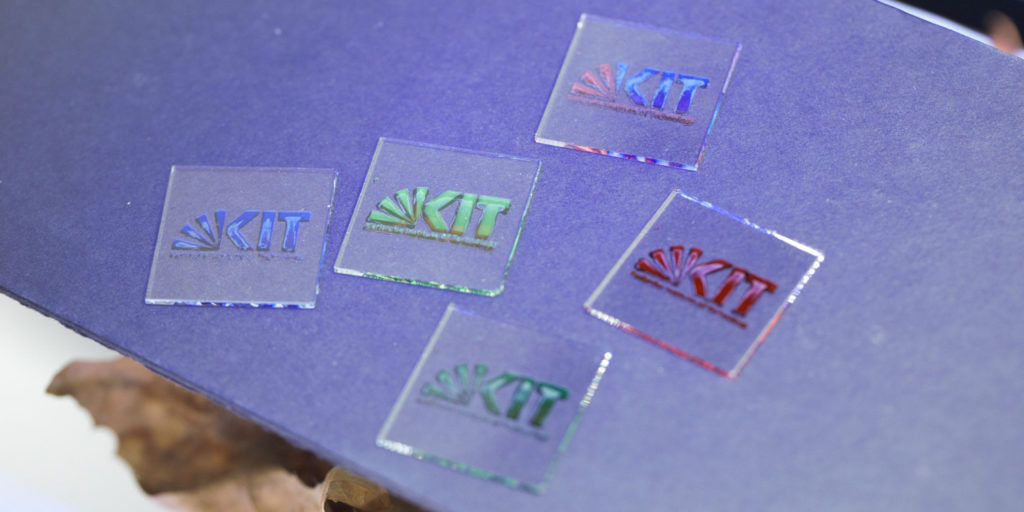

In addition to the stability of the modules, it is also important they meet the requirements for integration in buildings. As such, they would have to be developed free of size, shape and color constraints. To achieve this, the scientists used the potential of digital inkjet printing and developed printable luminescent layers to realize different color impressions and protect the solar cells from harmful UV radiation, KIT said.

Initial results published

To improve the stability of the perovskite modules, the project partners worked to connect several cells serially to a large-area solar module, while encapsulating the modules to protect them from moisture and associated degradation.

In addition to KIT, the Technological Educational Institute of Western Greece and PV manufacturers Sunovation Produktion GmbH and Britte Hellas are also involved in the Printpero project. The German-Greek research project started last year, is set to run for three years and is funded by the German Federal Ministry of Research, added KIT.

The researchers have already published initial results and the article Design and Color Flexibility for Inkjet-Printed Perovskite Photovoltaics can be downloaded free of charge.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I wonder if what architects are looking for is the pv equivalent of paint. Any pv system has to have wring to collect the power, and that can’t be painted on, it’s a discrete system with strict safety rules. I feel BIPV protagonists should be looking at discrete modules that can be part of the rigid cladding of a structure. Tesla had the right idea with solar tiles, even if they have not taken off.

Non-integration has one considerable advantage: flexible replacement. When your conventional rigid PV modules on the roof start failing after 30 years, or sooner if you bought a bad job lot, you can easily rip them out and put in new ones. If you have BIPV windows, you have to replace the expensive windows.