The direct burial of cables at PV power plants can be a cost-effective approach – ensuring that cabling is out of the worst weather conditions and cannot be damaged by maintenance crews or local critters. However, when the cables are not themselves fit-for-purpose, it can lead to their breaking down, potentially causing faults and fires.

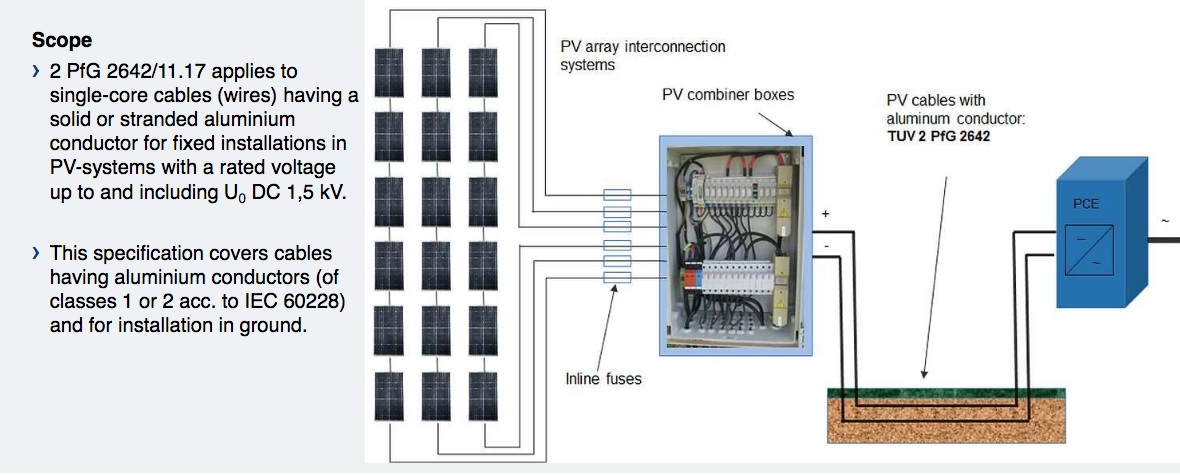

To tackle these issues, TÜV Rheinland published a new standard – 2PfG2642/11/17 – on October 31.

During a recent pv magazine webinar, Leoni and TÜV Rheinland discussed the new standard and what it means for the industry. You can now download their joint presentation and listen to the webinar, while the questions that time did not permit, have been addressed below.

Where is Leoni producing solar cables?

Jan Mastny, Head of Global Sales, Leoni: Leoni has three manufacturing locations: Däniken Switzerland; Pune, India; and Changzhou, China. The R&D center for cables and our compounding center, meanwhile, are located in Switzerland. This means that the insulation raw materials are developed and prepared in Switzerland. From there, we distribute the materials to all three locations, in order to secure the 100% identical cable properties worldwide.

TÜV Rheinland has developed the standard 2PfG2642/11.17 for direct burial cables. Is this a draft?

Guido Volberg, Head of Technical Competence Center PV Modules and Components, TÜV Rheinland: No, the document was released on October 31, 2018, as a final specification.

Why was this standard not developed at an international and/or European level at CENELEC/IEC TC20 & TC82, but rather as an “in-house” standard?

GV: It takes a long time to publish a standard in these committees when we start at “0”. So it can be seen as an advantage that we can already collect some experience with these standardized products. The document is also expected to be presented to the German committee, so that we can forward it later on to CENELEC and/or IEC as NWIP for an EN or IEC standard.

TÜV Rheinland is a testing institute and certification body. Why is it then making standards for cables?

GV: There is no reason not to make standards for products. VDE is creating VDE-User guidelines, UL is creating UL-subjects or standards, and TÜV Rheinland is creating TUV Rheinland standards (2 PfG).

What will this new standard tell us about the cable characteristics needed to be in permanent contact with water/humidity?

GV: If the cable described in 2 PfG 2642/11.17 is intended to be directly buried, it must have a metallic layer as protection against the ingress of humidity. Of course, this metallic layer must be closed and tight. We have installed string-cables in underground duct-systems. It has been seen that water finds its way into the ducts and, unfortunately, stays there. After finding isolation-faults in the cables and following discussions with EPCs and cable suppliers, the only type of cable that can be used in this situation (permanently covered with water) is one that fulfills the AD8 Standard in accordance to IEC 60364-5-51.

Does Leoni have experience with this and can you confirm that this standard is sufficient?

Faruk Yeginsoy, Head of Operations, Leoni Business Unit Solar & Windpower, Leoni: AD8 is correct, but all PV cables on the market are AD7, and in all PV cable standards, AD7 is required. To be honest, a real AD8 cable without any metallic protection layer is not possible. In this case, you have to make sure that the water can drain.

With the rise of floating PV, does this standard also cover the installation of cables in fresh or even sea water? If not, is there any standard related to power cables for floating PV parks?

FY: With the state of the art cable compounds, sea water is not a problem.

Leoni has presented its SolarPower Alu-ATA XS cables as a solution that meets the new standard. Is the double insulation requirement only for solar cables, or for all from modules to inverters? What is the background for this requirement?

FY: Because almost all PV installations are class II installations (ungrounded) the double or enforced insulation is mandatory for safety. This requirement is for all cables on the DC side.

Will there be additional losses from metallic protection due to eddy current loss?

FY: Not at all. Eddy current is only possible with magnetic materials, not with aluminum. Anyway, here we are talking about DC. In DC there is no eddy current.

Does the cable have cable have anti-rodent and termite properties?

FY: Yes! And it is tested by a German Governmental institute in Berlin.

What is the cost difference between anti-rodent and normal cables?

There is no difference because we only have the protected version.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Where can this standard 2 PfG 2642/11.17 be purchased?