One of many research groups the world over working to unlock the commercial potential of perovskite solar cells, researchers from the Energy Materials and Surface Sciences Unit at OIST have developed a process, which they say could be scaled up for use in commercial production.

The low-cost, high efficiency potential of perovskites has long been known, and research has pushed the development of the technology at an impressive rate. “Research on perovskite cells is very promising,” says OIST Professor Yabing Qi. “In only nine years, the efficiency of these cells went from 3.8 % to 23.3%.”

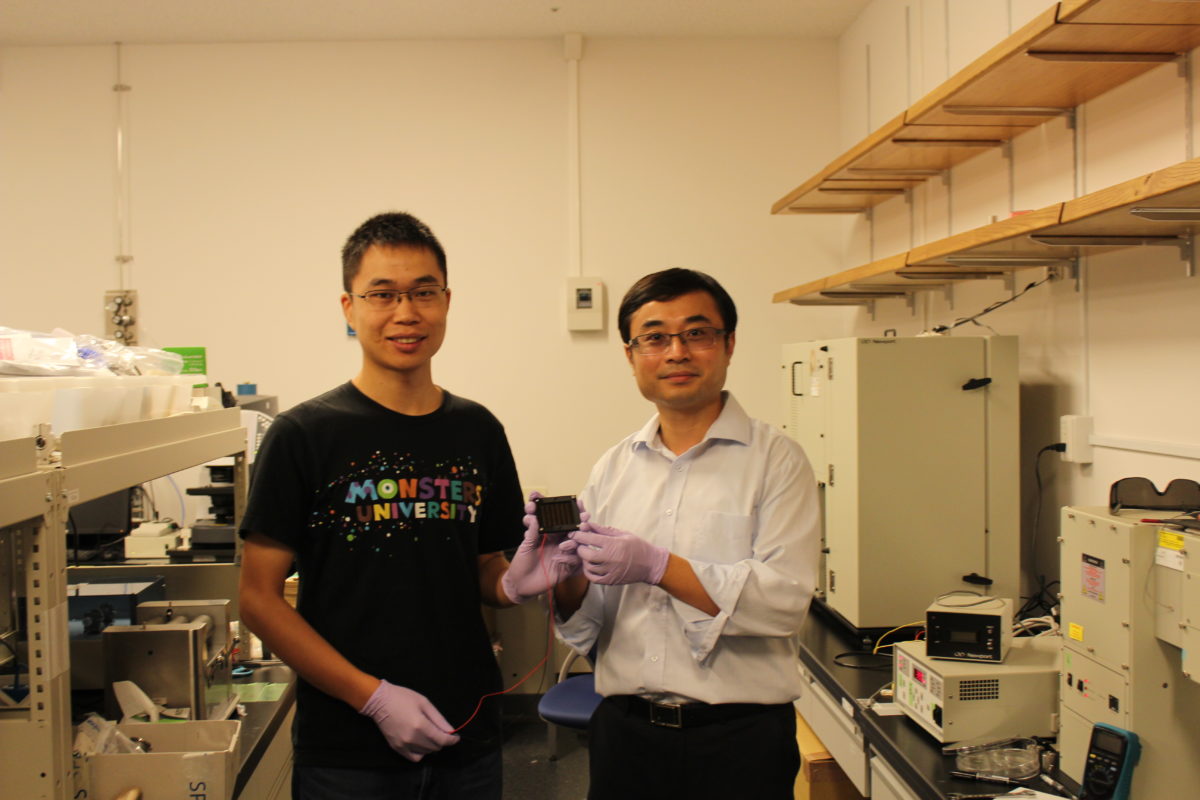

The device developed by the OIST group, described in the article ‘Gas-solid reaction based over one-micrometer thick stable perovskite films for efficient solar cells and modules’, and published in the journal Nature Communications, was created using a gas-solid reaction-based technique, in which the substrate is first coated with a layer of hydrogen lead triiodide incorporated with a small amount of chlorine ions and methylamine gas, which the researchers say allowed them to make uniform, reproducible panels.

Key to their method, says OIST, was the use of a 1-micron thick active perovskite layer. This thicker coating is said to boost stability of the solar cells, as well as simplifying the production processes, thereby lowering costs. The researchers were able to scale up their process from a prototype measuring 0.1mm², to a module based on 5x5cm² cells. Although scaling up the size significantly reduced the cell efficiency, from 19.1% to 15.3%, the team says it will now focus on improving this, and is confident that the process will be ready for commercial use in the coming years.

U.K.-headquartered perovskite specialists, Oxford PV, meanwhile, appear to be leading the charge for commercialization of perovskite technology, having recently announced plans for a research partnership targeting 37% efficient perovskite cells. The company previously told pv magazine that it has successfully scaled up its perovskite on silicon tandem cells to ‘full size’ 156 x 156mm, with only “a small difference” in efficiency, compared with research sized devices.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.