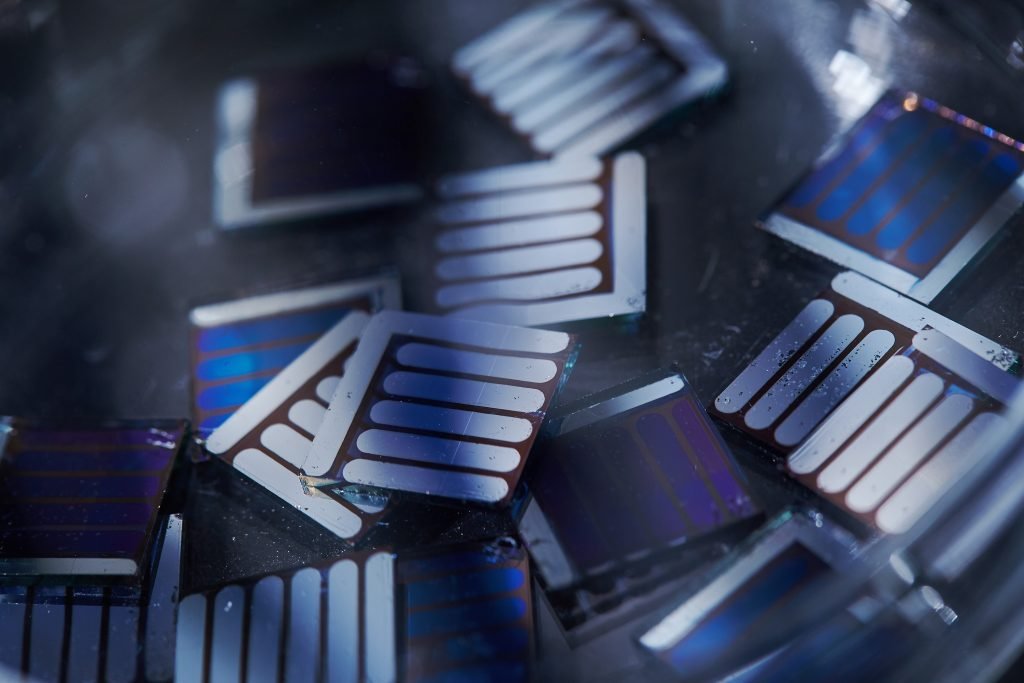

Researchers at the Ulsan Institute of Science and Technology (UNIST) have reached 12.01% efficiency on an organic solar cell (OSC), using a process which they say solves many of the complexities that have kept organic PV from large-scale production, in particular an issue of efficiency loss, where the active cell layer is much thicker than 100 nanometers.

The process, described in the paper Ultrafast Channel II process induced by a 3-D texture with enhanced acceptor order ranges for high-performance non-fullerene polymer solar cells, published in the journal Energy & Environmental Science, utilizes a non fullerene acceptor, and demonstrated efficiencies close to 10% when the active layer thickness was increased to 300nm.

“Photoactive layers in the existing OSCs are rather thin (100 nm), and therefore it has been impossible to handle them via large-area printing process,” explains Changduk Yang, Profesor at UNIST’s School of Energy and Chemical Engineering. “The new photoactive layer maintained its initial efficiency, even when the maximum measured thickness being in the range of 300 nm.”

This breakthrough, according to UNIST, could allow for the development of large-area printing processes, which could lead to production costs low enough to compensate for the conversion efficiencies achieved with other technologies.

“This study highlights the importance of optimizing the trade-off between charge separation/transport and domain size to achieve high-performance NF-PSCs [non-fullerene polymer solar cells],” says Professor Yang. “Our study presents a new pathway for the synthesis of non-fullerene photoactive materials, we hope to further contribute to the production and commercialization of high-efficient OSCs cell.”

Earlier in 2018, scientists at New York University's Tandon School of Engineering used a crystallizing agent to pass 10% efficiency on a non-fullerene organic cell, while another U.S. research team managed to stack two different organic solar cells on top of each other, achieving 15% efficiency in the process.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.