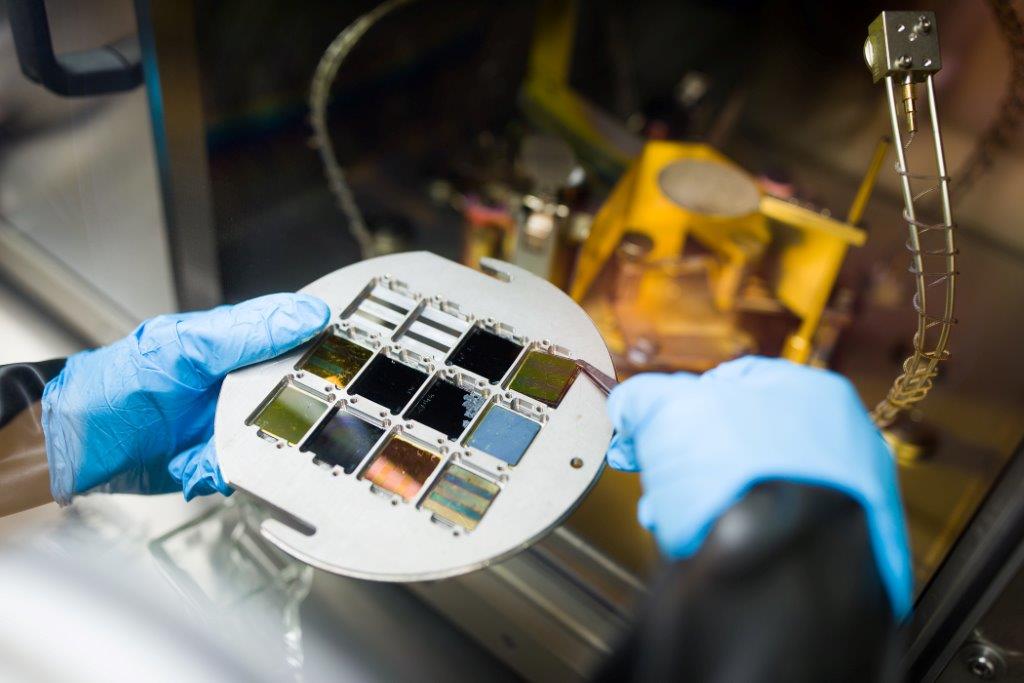

The HZB and the University of Oxford have collaboratively announced a 1 cm2 perovskite-silicon two-terminal tandem solar cell with 25.2% conversion efficiency. The HZB team worked with the Photovoltaics and Optoelectronics Device Group at the University of Oxford, led by Professor Snaith.

Commenting on the result, Rutger Schlatmann, the Director of the Competence Centre Thin Film and Nanotechnology for Photovoltaics Berlin (PVcomB) at HZB, said, “Perovskite-based tandem solar cells can use light particularly efficiently and therefore offer the opportunity to achieve even higher efficiencies.

“That is why we have significantly expanded our expertise with the new Helmholtz innovation laboratory HySprint […] For this new result we have optimized our high-efficiency silicon heterojunction bottom cell and developed an optical adaptation to the top cell using a very specific SiOx intermediate layer.”

The efficiency result is one of a number of developments in perovskite technology announced in recent weeks.

Researchers at the Centre for Hybrid and Organic Solar Energy (Chose) of the University of Rome produced a perovskite cell with maximum power density, under white LED illumination, of 20.2 µW/cm2 at 200 lx and 41.6 µW/cm2 at 400 lx, equivalent to a conversion efficiency of 27%.

The exceptional performance under the LED lighting was achieved by incorporating new solution-processed SnO2/MgO composite electron transport layers between the perovskite semiconductor film and the bottom transparent electrode. The thin MgO upper layer enhanced the efficiency by ~20%, reducing charge recombination which is especially important at the low light levels typically found indoors. Results have recently been published in Nano Energy.

In Switzerland, a team at EPFL announced a perovskite-silicon heterojunction cell with a 25.2% conversion efficiency that reportedly can be produced at low costs, as it retains the silicon substrate surface structure.

Solar PV scientists indicate that the theoretical limits of conversion efficiency of silicon cells is coming in very close to being reached. Perovskite tandems is emerging as a promising technology to push efficiencies beyond this limit.

A significant level of research funding has flowed to perovskite tandems. For example, Norway’s Equinor (former Statoil) provided Oxford PV with GBP8 million (US$10.6 million), in April this year. At the same time, the pan-European CHEOPS project is investing in research institutes at various institutes throughout Europe.

Commercial production

Commenting on the latest collaboration between Oxford PV and HZB, Chris Case, Chief Technology Officer at Oxford PV said: “The unique, optically enhanced architecture developed as part of this collaboration, minimises losses, and has helped us achieve this record setting efficiency. With our combined progress in efficiency, stability and reliability, our perovskite-silicon tandem solar cell technology is now reaching its commercial potential.

While most efficiency results with perovskite tandems have been achieved in the laboratory, Oxford PV is currently attempting to scale its technology.

“As with any new technology,” continued Case, “the biggest challenge is transferring the technology from the lab and scaling up to high volume manufacturing. The company has already made great progress in this respect and our industrial pilot line is producing commercial sized 156 mm x 156 mm perovskite-silicon tandem solar cells for validation by our development partner – a major manufacturer of silicon solar cells and modules.”

The silicon-perovskite tandem efficiency records, above 25%, are a welcome development, noted HZB’s Steve Albrecht whose HZB team also developed a certified a tandem solar cell with 25.0% recently.

“There is no correlation between the tandem efficiency results posted by the different research consortia except that the consortia in which HZB was involved implemented the same optimized silicon bottom cell processed at HZB,” said Albrecht, a young investigator group leader at HZB for perovskite-based tandem solar cells, in an interview with pv magazine. “The scientific community hasn’t posted any records for a while in this segment, so it was about time, that somebody achieves a new record. That now three research institutes do so within a matter of two weeks, is just a coincidence.”

The various research groups have taken different approaches to silicon-perovskite tandem architectures. The cells presented by HZB and Oxford PV are use flattened silicon surface upon which the perovskite is applied. The silicon surface usually exhibits microscopic pyramids about 5 microns high. These pyramids help trap sunlight hitting the cell. However, researchers found that applying perovskite onto this surface structure is challenging.

Surface challenges

EPFL/CSEM’s recently presented research showed a method by which the pyramid structure could be retained. According to EPFL this enables the cell to benefit from the pyramid structure, delivering higher efficiencies. More importantly, the structure retention means that the costly “flattening” of the pyramids is not required. EPFL says that tandem cell production costs can thus be greatly reduced.

“The research posted by EPFL, using texturized silicon surfaces, is fairly remarkable and impactful for the segment,” added HZB’s Albrecht.

While perovskites can post great conversion efficiencies they do, however struggle with stability. Albrecht explains that a lot of research has been done recently to improve perovskite stability, when exposed to light. According to the researcher, many perovskite and perovskite tandem cells can now withstand several 100 to 1000 hours of full light exposure, while retaining most of their conversion efficiency. Not yet competitive with current silicon modules, but a clear and significant improvement nonetheless.

A team at Stanford University even achieved a 1000h full light exposure resulting in no conversion loss, he adds.

Another downside of perovskite is the toxicity, it is reported, as the perovskite structure contains lead. “It is true that the structure contains lead, but the perovskite film is just a few hundred nanometres thin, so it doesn’t contain much lead,” said Albrecht, “and a very recent study by CHEOPS project partner SmartGreenScans from the Netherlands, specialized in life cycle analysis (LCA), however, seems to indicate that the lead component only contributes to a very minor extent to the overall eco-balance in a silicon-perovskite based tandem modules.

“Still, there are efforts to investigate new ways of reducing or fully eliminating the use of lead, by for example replacing it with tin or utilizing so called ‘double perovskites' with other elements.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.