Japan-based Toshiba Energy System & Solutions Corporation (Toshiba ESS) made an announcement on Wednesday, according to which Toshiba and Iwatani Corporation have started a demonstration of a holistic supply chain of hydrogen for electricity generation.

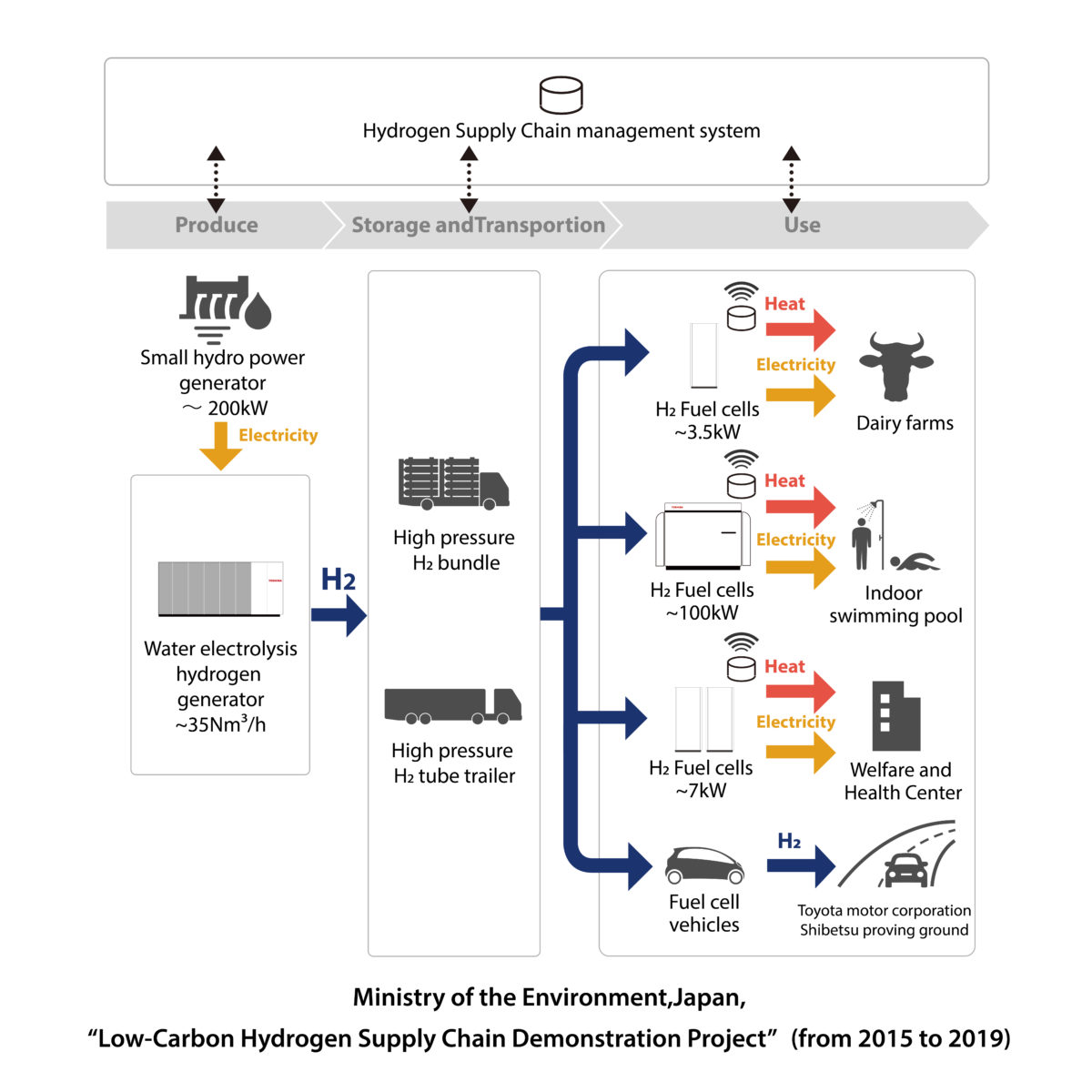

Toshiba ESS constructed a 200 kW hydropower plant at the Shoro Dam in Shiranuka, near to Hokkaido’s pacific coast. The plant is used to power a hydrogen electrolysis facility, with a capacity of 35m³ of hydrogen per hour. The gas is then transported by Iwatani to Toshiba ESS hydrogen fuel cell systems located at dairy farms, an indoor swimming pool, and a welfare and health centre near the hydrogen generation facility. Additionally, a portion of the hydrogen will be delivered to Toyota’s Shibetsu proving ground for fuel cell vehicles.

Toshiba ESS cites Hokkaido’s abundant renewable energy resources, including wind, hydro and PV. Implicitly, the hydrogen supply chain could be powered by PV rather than hydro power.

With the increasing installations of renewable energy, energy storage, and therefore power to gas, have become a hot topic for everybody involved in the sector. Hydrogen, however has struggled to compete against lithium-ion batteries, as its efficiency for power conversion has been very low. The initial loss during the electrolysis is around 30%, with a further 5-10% lost during transport as a result of cooling and compression of the gas. Another half of the potential energy dissipates into heat, rather than electricity during its final conversion in the fuel cell.

This, coupled with the fact that average costs of hydrogen production reached €0.10/kWh rendered the technology not competitive with lithium-ion storage. But still a range of companies are clinging to the idea and continue the research. The Institution of Mechanical Engineers just recently urged the UK goverment to expand its efforts to promote power-to-gas, as they believe it could very well be a viable alternative to fossil fuels. While hydrogen can't compete with the prices of lithium-ion storage in storage facilities and EV's it can very well find applications in larger vessels and trains.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

If the electrolyzer is 70% efficient; if the transport and storage of H2 is 100% efficient and if the fuel cell is 60% efficient, then the total conversion of hydroelectricity to H2 and then back to electricity by a fuel cell is only 42% efficient. If the transport and storage of H2 is 90% efficient, then the round trip efficiency is only 37.8%.

Thyssenkrupp have now developed a high efficiency electrolyser with 82% efficiency, and a low capital cost. This means much cheaper hydrogen.

The problem with lithium batteries is that only a few hours of energy storage is possible. With hydrogen, and salt-cavern or on-site storage, almost unlimited quantities of energy can be stored. Conversely, the hydrogen can be methanised and fed directly into the gas network.