First Solar dropped a bombshell just before its quarterly results call today, reporting that it will build a new thin film solar factory in Ohio. The factory and its 500 workers will have the capacity to produce 1.2 GW of the company’s large-format Series 6 modules when fully ramped, which is expected by the end of 2020.

This will make it the largest solar factory by capacity in the Western Hemisphere – larger even than the fully ramped capacity of the Tesla/Panasonic solar gigafactory in New York State* – and will triple First Solar's U.S. manufacturing capacity.

“This decision is a response to the continuing strong demand for our Series 6 product,” explains CEO, Mark Widmar. He stated that it is also testament to the potential of U.S. solar manufacturing.

This statement is in sharp contrast to the statements of analysts at IHS Markit and GTM Research that new cell and module factories in the United States do not make economic sense, despite the imposition of tariffs on imported modules.

First Solar cites the recent U.S. tax reform and “favorable business environment” as reasons why American manufacturing makes sense. Additionally, CEO Widmar notes the lower labor cost per watt of its Series 6, which reduces the labor arbitrage benefit of building modules in Malaysia or Vietnam.

The Trump Administration was quick to claim credit for the factory. “This is exactly the result we had hoped for, and are delighted that First Solar reacted so quickly,” stated U.S. Commerce Secretary Wilbur Ross.

Widmar also says that the new factory can leverage its R&D and manufacturing in the Perrysburg, Ohio factory, which it will be built near. The new plant in Lake Township, Ohio is expected to occupy 1 million square feet of floor space, and represent an initial investment of $400 million and $30 million in annual payroll.

Since its founding, First Solar estimates that it has invested $3 billion in Ohio, including wages paid, manufacturing purchases, research and development spending, and taxes.

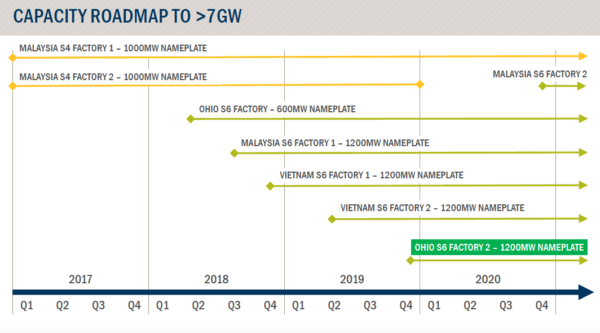

Widmar has also revealed that the new factory will not replace its plans for retooling in Malaysia and Ohio, or its twin factories in Vietnam, but will be in addition to its prior plans. As such, the company plans to reach a total of 7.6 GW of annual manufacturing capacity by the end of 2020.

*Editor's note – Tesla plans for the factory to be at 1 GW of annual cell capacity by the end of 2019, and has set a goal for 2 GW at an unspecified future date.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.