While the Section 201 case is clearly a threat to the downstream U.S. solar market, there is increasing evidence that it will lead to an expansion of U.S. solar cell and module manufacturing. As the industry waits for President Trump to deliver his decision on trade action before January 26, there are already signs that at least three manufacturers are seeking to expand or establish operations in the United States.

Following Florida PV maker SolarTech Universal’s announcement that it plans to hire more than 100 workers this year and establish production in Puerto Rico, and the news that an un-named global PV maker is negotiating with Jacksonville, Florida for potential manufacturing, today California’s Solaria Corporation announced new funding and an expansion of its production.

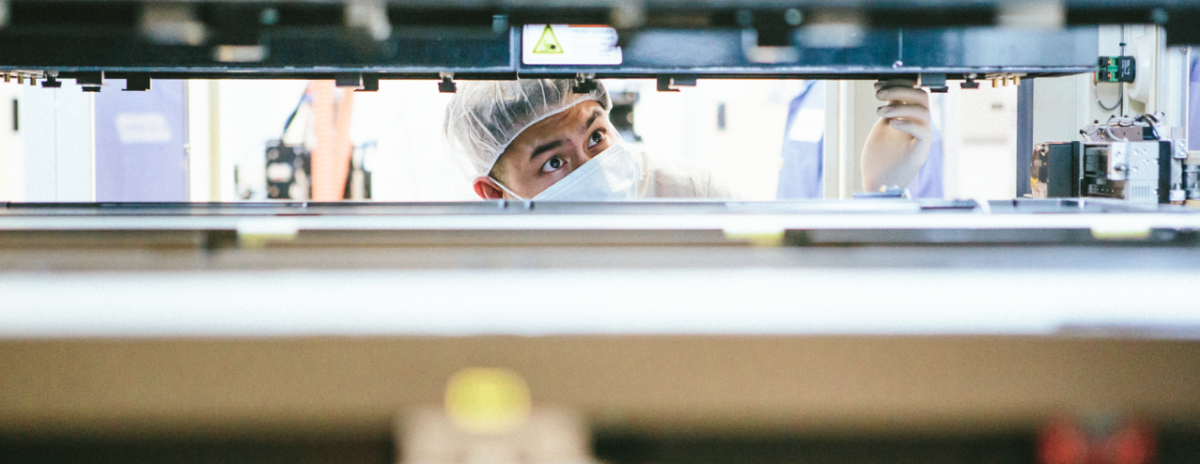

Solaria, which makes a suite of solar products including high-efficiency crystalline silicon solar using a proprietary cell interconnection and module assembly process, reports that it has raised $23 million from a syndicate of investors. The company says this will enable it to expand its manufacturing capacity both in the United States and South Korea, where it makes PV products in collaboration with an OEM manufacturing partner.

Solaria has been around since 2000 and spun off the leading tracker maker by marketshare (NEXTracker), however its PV cell and module products have remained niche. Currently Solaria has the capacity to make 100 MW of its high-efficiency PowerXT modules annually between Korea and Silicon Valley, but says that by the end of 2018 it expects to expand this to 300 MW.

The details will be different. In Korea Solaria expects to be able to expand within the existing facility where its modules are made, however its facility in Fremont, California is maxed out and the company has begun the search for a new location to install production lines.

Solaria expects this process to take around 4-6 months, but says that it expects to ramp production following that in less than 18 months. The company notes that it will be looking for existing facilities to add its lines, and not starting construction on a new building, which should make the process faster.

In addition to its PowerXT modules Solaria also makes building integrated photovoltaic (BIPV) architectural glass products. And while the new expansion is focused on PowerXT, Solaria’s CEO notes that the equipment can also provide material for BIPV products, which are assembled on separate lines.

“(PowerXT) is higher growth right now while we are seeding the market for our architectural solar business,” Solaria President & CEO Suvi Sharma told pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

9 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.