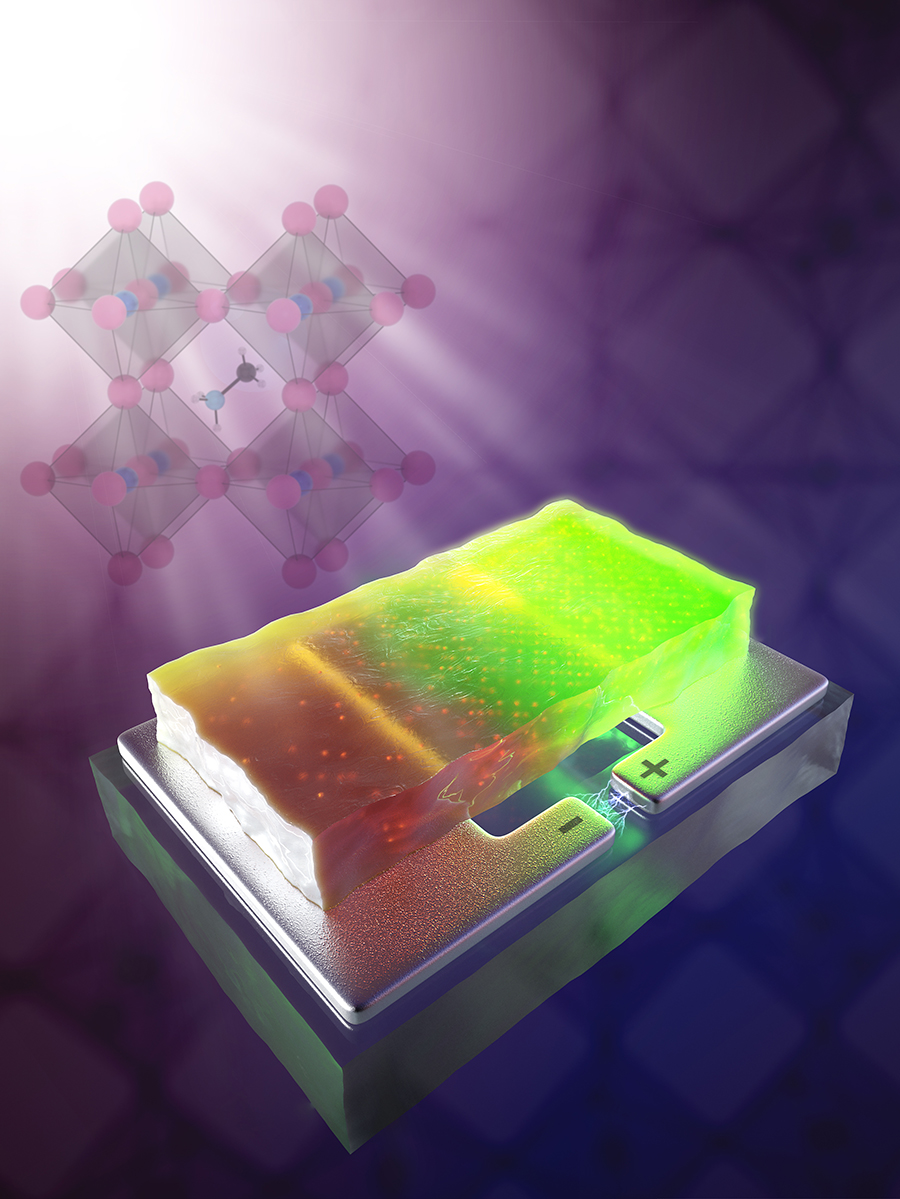

A technique named nanoprobe X-ray fluorescence has allowed scientists to observe degradation mechanisms at work at the nano-scale in a lead based hybrid perovskite material.

Working with the material methylammonium lead bromide, which contains negative bromine ions. As with other perovskite materials, the crystalline structure contains multiple gaps, which have long been theorized to allow ions to move within the material when voltage is applied.

The inherent instability of many perovskite materials has made them difficult to study, as many microscopic techniques quickly cause damage to the material, or cannot see beyond the surface. With nanoprobe X-ray fluorescence, however, the researchers were able to measure and create high resolution maps of the atoms making up the material.

These maps revealed bromine ions migrating from negatively to positively charged areas. After this, shining a laser onto the perovskite revealed that areas with higher bromine concentrations had up to 180% stronger photoluminescence than the areas depleted of bromine ions.

“We watch the bromine ions migrate within minutes, and see that the resulting bromine rich areas have the potential to become better solar cells, while the performance is degraded in bromine poor areas,” explains David Fenning, Professor of nano engineering at UCSD. “Ion migration hurts the performance of the light absorbing material. Limiting it could be a key to improving the quality of these solar cells.”

Armed with this knowledge, Fenning and his team will now work on methods to limit bromine migration methylammonium lead bromide, and apply their knowledge to other perovskite materials. UCSD points to different methods for growing the hybrid perovskite crystals, and reducing the number of defects within the structure as a likely way to achieve this.

Recently, Polish scientists saw success in this area, by replacing usual solvent based processes with solid compounds in a steel ball mill, and a leading international group of researchers discovered a way to ‘heal’ such defects using light and humidity.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.