If several module strings fail completely, the result is usually high yield losses. At that point, it is worthwhile to find out exactly where the faults are and correct them. But even string failures can pose challenges, as evidenced by an actual case involving O&M company Ensibo in a pitched roof system running parallel to the roof.

The plant: parallel-mounted, pitched-roof system with thin film modules and 4 MW of capacity, which Ensibo acquired as an existing system. The plant was built in 2009 in Germany.

The monitoring system reports: Monitoring initially reveals that, for its size and location, the total plant produces a yield that is 6% too low in two of the three subsystems (approximately 1,700 kWp). Six module strings with eight modules each are interconnected for monitoring. The yield data of the individual measuring channels in the junction boxes (GAKs) are very different, although the conditions in the system are actually relatively uniform, with regard to the orientation and inclination of the modules, for instance.

The hypothesis: There are no visible signs of any unusual features on the front side of the modules, and the rear side of the modules cannot be visually inspected due to the roof-parallel installation method. In view of the plant’s reduced output, the operator suspects that entire module strings may have failed.

Identifying the fault and the affected modules: Two factors would make it more difficult for a technician on-site to perform a string measurement: First, the backs of the modules can only be accessed with great effort due to the lack of maintenance openings and the installation method parallel to the roof. Additionally, the panels are thin film modules, which are connected in series in groups of eight modules with six sub-strings connected in parallel. The failure of a sub-string causes only a 17% lower string current at the generator junction box, which can only be detected under favorable weather conditions.

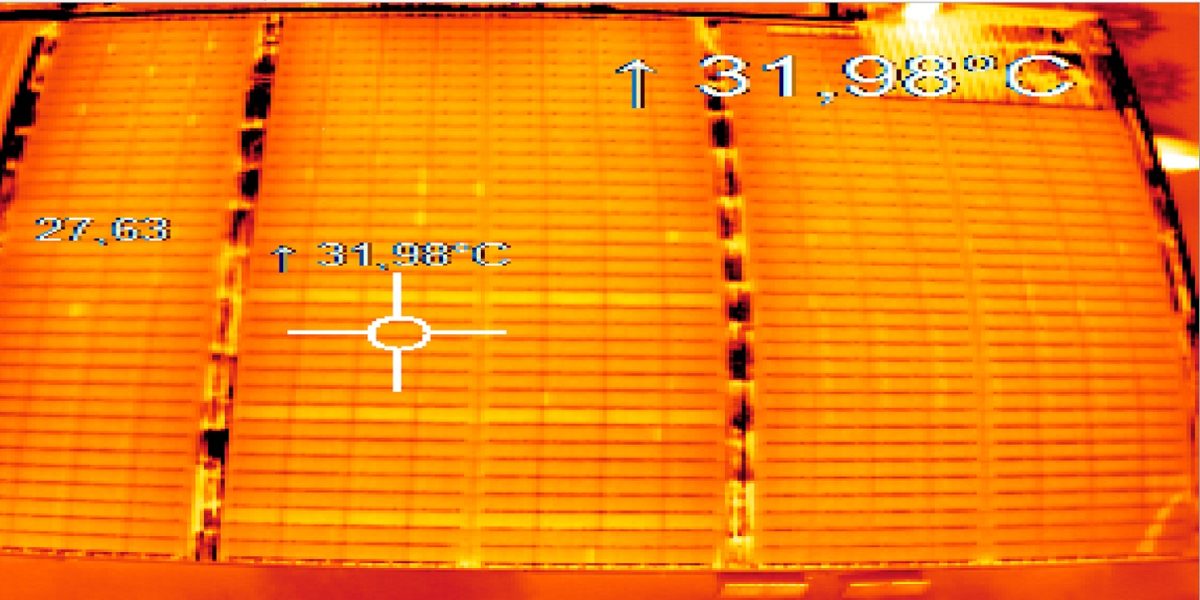

But this still does not localize which sub-string is affected. The plant manager therefore recommends that the operator carry out a drone-based thermographic survey of the entire plant for around €2,000. An external service provider takes the images and sends them to the plant manager. The result confirms the manager’s suspicion. The thermographic image shows that 20 module sub-strings have failed either completely or partially, and identifies the individual modules affected. It is likely that the problem has existed for several years.

Photo: Ensibo

Ensibo is an independent service provider for the technical operation of solar power plants and offers monitoring, fault management, maintenance and reporting. Based in Hamburg, ensibo monitors about 100 megawatt peak from plants in Germany and Kazakhstan. Ensibo's own employees inspect and maintain solar parks nationwide. In the event of a fault, numerous qualified local partners are available for quick and economical repairs.

Results of the investigation: The plant manager transfers the results of the thermographic examination onto a diagram of the modules and sends a technician to the plant. Based on the module diagram, the technician can repair the individual modules and strings in a targeted manner. He discovers a large number of module connectors are disconnected. These were probably not reconnected following a major rebuild of the plant in 2012.

The technician found no defective plugs in the system. He reconnected the disconnected plugs. The repairs increased the yield of the plant by almost 1%. With the 2009 feed-in tariff averaging €0.37 per kilowatt hour, the plant generated an additional €3,700 per year after repair.

Effort of troublesooting in this case

Estimated cost of troubleshooting following the monitoring alarm:

€2,200.

Estimated waiting time until the module faults were located:

three months.

Estimate of how long the diminished yield probably already existed:

five years

Ensibo acknowledges this case as unique.

pv magazine troubleshooting series:

- What happens when… bypass diodes fail?

- What happens when… modules get dirty?

- What happens when…insulation fails?

If you are interested in participating in similar cost estimates or have suggestions for a more efficient handling of the faults, we look forward to receiving an e-mail from you: Please contact michael.fuhs@pv-magazine.com (subject line: “troubleshooting”).

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

You would think checking basic output and connectors would be part of a monthly if not weekly plant check up. We’re those connectors clearly visible and east to access? Don’t they use hand held thermAL reading monitors on all panels and connectors to watch for hot spots ?