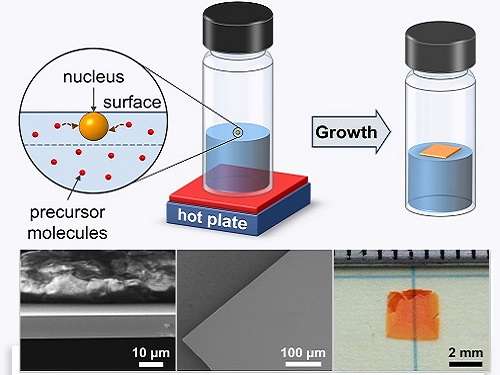

Scientists at KAUST’s Solar Center have been working on ways to speed up the flow of charge carriers in perovskite crystal, using a technique known as inverse temperature crystallization (ITC), which utilizes organic liquids and thermal energy to force the perovskites to solidify into single crystal type structures.

Ayan Zhumekenov, a PhD student at KAUST, noticed key evidence whilst working on measures to adapt ITC processes towards large-scale manufacturing. “At some point, we realized that when crystals appeared, it was usually at the solution’s surface,” recalls Zhumekenov. “And this was particularly true when we used concentrated solutions.”

The team from KAUST then partnered with scientists at Oxford University, in order to better understand this discovery. They found that complexes located at the solution’s surface crystallize differently, due to the effect of surface tension. Extra pull provided by the surface make it much easier to separate crystals from the complex.

Armed with this newfound knowledge, the researchers were able to produce ultra-thin single crystal perovskites at centimeter scale. While these crystals are currently far too fragile for application in commercial solar manufacturing, Zhumekenov holds that the method developed could help to direct perovskite growth on specific substrates.

“Taking into account the roles of interfaces and surface tension could have a fundamental impact,” explains Zhumekenov. “We can get large area growth, and it’s not limited to specific metal cations, you could have a library of materials with perovskite structures.”

U.S. and Chinese scientists recently developed the first working cell using single-crystal perovskite, and achieved 9% efficiency with this. KAUST has made some major investments in its Solar Center over the past year, and produced several steps forward in perovskite research as a result.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.