The problem of soiled solar panels is an issue as old as PV itself. Contemporary understanding of soiling, however, is helping to mitigate the negative effects of dusty or dirty modules – which can not only lead to reduced power output but can also cause hotspots to occur.

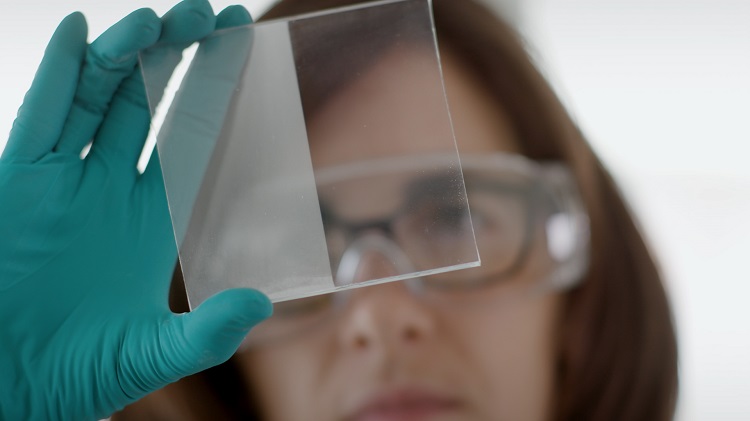

The Netherlands-based backsheet and coatings specialist DSM has recently introduced a new anti-soiling coating for solar modules that it claims can boost the average power output against modules treated with its own anti-reflective coating.

These gains in efficiency were recorded at the TÜV SÜD test site in Dunhuang, China, in ongoing field tests that began last year. Here the anti-soiling coating outperforms DSM’s own anti-reflective coating – that already provides 3% extra power gain – each month by more than 1.3% on average. The coating was developed to help investors in solar farms boost their internal rate of return (IRR) at a time when margins – particularly in emerging markets in hot and dusty climates such as India and the Middle East – are increasingly tight.

“DSM has been a leading player in anti-reflective coatings for a while, and we have recently launched a new anti-soiling coating for PV glass that will bring significant benefits in terms of energy output and more cost-effective maintenance of solar parks,” said Jan Grimberg, DSM’s business director solar.

Launched at SNEC in China, the coating will be presented at the SPI show in Las Vegas next month, and Grimberg is hopeful that its appeal will be universal. “We have tested it extensively at various sites, and the data shows that, compared to our traditional anti-reflective coating, this special coating has a number of benefits for solar parks in dry, desert-like environments with high UV loads.”

Solar panels that have anti-soiling properties require fewer cleaning cycles and thus less labor and maintenance – something that is paramount in remote regions where rolling a cleaning truck to a solar farm can be cost-intensive if done too often.

“The anti-soiling properties will last,” Grimberg stressed, “because we make use of inorganic components rather than organic ones, which would more easily degrade.” DSM’s coating technologies are present in more than 50 GW of modules worldwide, with the company calculating that this adoption by the solar industry of DSM products has helped to mitigate 2,300 ktons of global CO2 emissions.

“We are now reaching out more directly to project developers, EPCs, and investors further downstream because our developments and value propositions are particularly relevant and important to them,” said Grimberg.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.