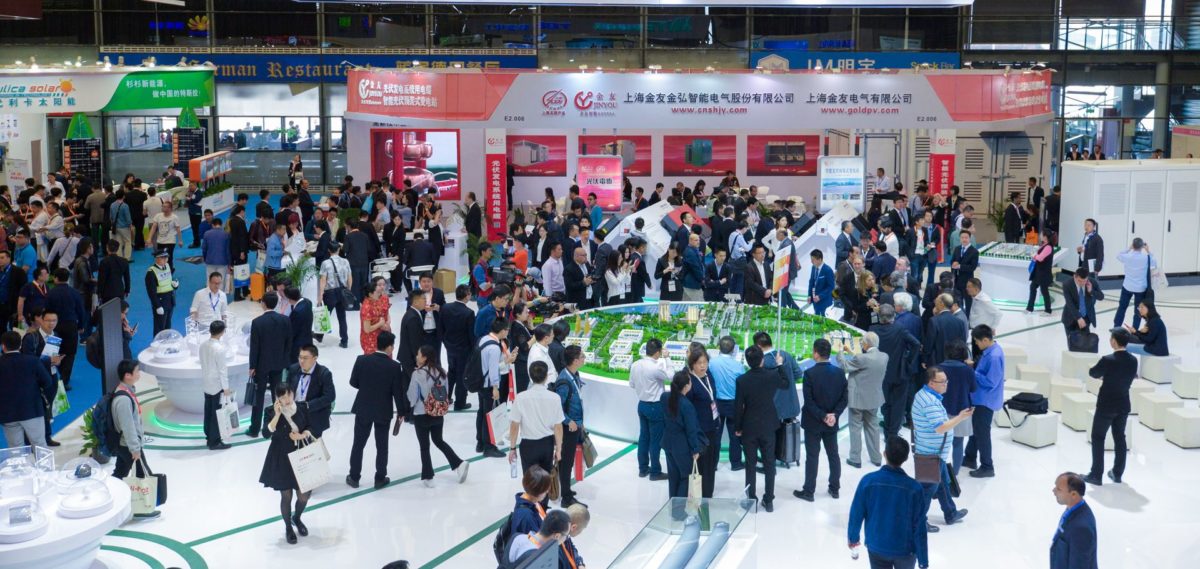

At the 2017 SNEC show in Shanghai, pv magazine investigated current market conditions for passivated emitter rear contact (PERC) equipment and technical challenges. Leading PERC equipment supplier Meyer Burger said that demand for the solution remains strong, despite challenges with LID in multi PERC applications.

But it appears that solutions to the LID challenge may not be far away. pv magazine spoke with some of the leading researchers and equipment makers working on removing the barriers to multicrystalline PERC production.

At Intersolar Europe in Munich next week, pv magazine will be holding a Quality Roundtable forum, at which issues relating to LID prevention and detection via monitoring will be discussed. Register, for free, here to take part.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

So- fine, a solution coming nearer. But what about all the PERC Stuff (also Mono) which already in the market? Are the manufacturers really acting in a reponsible way? In Germany many questions raises as it seems that problems with PERC- LID are rising on the back of installers and consumers.

Reponsible acting is different- I really strongly recommend everyone the buy any PERC only with doing a testing (how to perform alrready in the module purchase contract!) and hold payment back until it is 100% clear that the modules are not affect or maybe compensation is paid if so. If that not possible don`t use any PERC! You may loose a lot of many as other generations of new technology “test dummies” (the installer and consumers) did before …

Read my latest German blog on that maybe “New PID desaster for the industry?” and speak out clearly and loud what you may experienced with that at the quality round table of pvmag at Intersolar (p.s. Solarworld -“the mono PERC company” is not exhibiting …!)

https://blog.neue-energiewelt.de/2017/05/22/droht-der-solarbranche-ein-zweites-pid-desaster-perc-module-zeigen-nach-aussagen-im-markt-z-t-massive-degradation/

Customers of pv plants are not reacting quickly on power losses because of the lack of functioning monitoring systems. The way plants today are being monitored if residential, commercial or utility scale – it will not disclose LID nor PID. For this we need to measure every module and have artificial intelligence to do the analysis. The IoT world is doing similar math with great success. SunSniffer OS is the only system which is detecting LID or PID in pv plants among other risks. Risk mitigation is often been seen as cost and not as part of the ROI. Thank you for initiating awareness. This is missing at the first place.