Independent research group Chemitox Inc. tested modules produced on this client’s production line, based in Yamanashi prefecture, Japan. The modules tested were produced under normal conditions with a CIGS layer less than 1 micron thick.

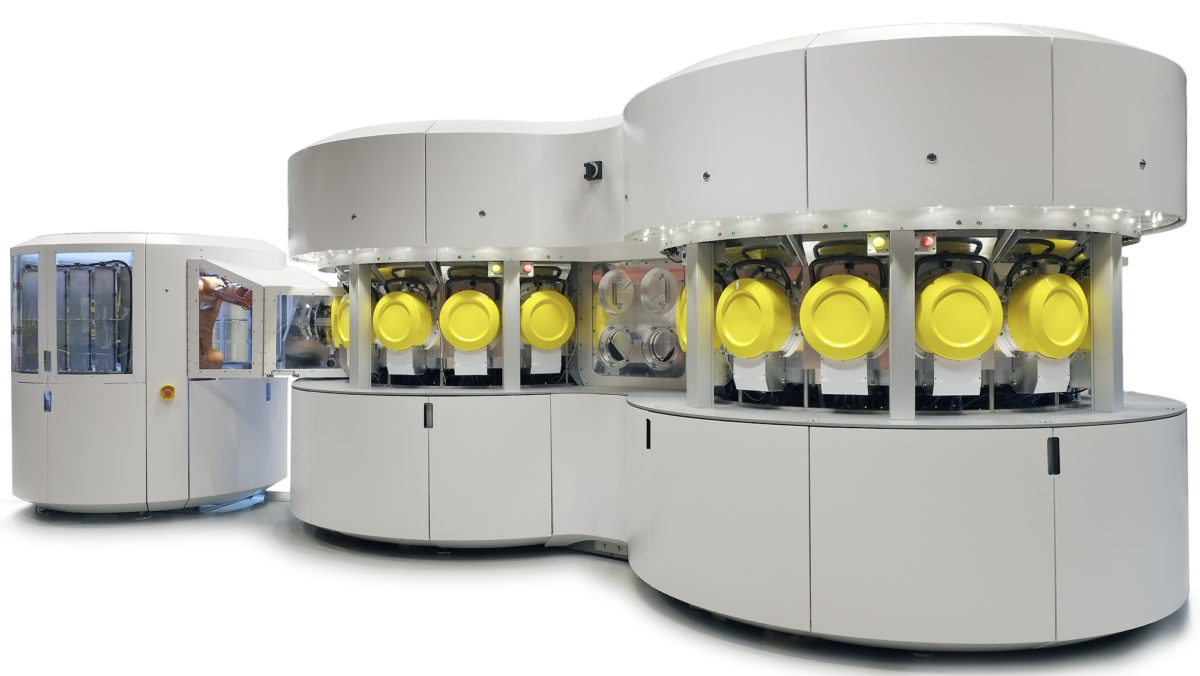

Back in May 2016, Midsummer announced that they had received orders for their DUO flexible substrate CIGS production tool from the unnamed Asian client.

“I am happy to announce that our solar modules have increased conversion effiiency to 14%. The DUO system is now the most widely spread manufacturing tool for flexible CIGS solar cells,” said Midsummer CEO Sven Lindström. “Lightweight flexible modules are the future of solar energy, since they can be fitted on to buildings, vehicles etc.”

Asian companies are moving into the CIGS manufacturing space, as they look to stay at the forefront of technological developments in PV. Earlier this week, Shenhua Group and Shanghai Electric placed a massive tool order, and announced a further collaboration with German tool maker Manz.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.